FABRIC INSPECTION

IQMS inspectors at your service perform on-site inspections in Sri Lanka, within 48H, based on your requirements and international inspection standards.

All - Inclusive

From US$ 200 !

BOOK NOW

determine whether

they are an

environmentally

responsible supplier

What is Fabric Inspection?

Fabric inspection helps understand quality in terms of color, density, weight, printing, measurement, and other quality criteria prior to garment production.

Based on your quality standards and product specifications, IQMS inspectors visit your vendor’s site to conduct a physical inspection of goods on a randomly selected sample of manufactured products using the statistical sampling procedure.

For inspecting the fabric, garment units use some kinds of inspection systems like the 4-point system,10-point system, or random checking of fabric (5-10% of total fabric length). IQMS inspection system base 4-point system testing protocol, an inspection technique that is extensively recognized for fabric.

The main purpose for inspecting fabric is the detection of quality issues and non-conformities at an early stage of the production process. Therefore, it will help the fabric buyers to not waste time, and money later on, in either correcting the defect or writing off defective goods.

IQMS can arrange a Fabric Inspection within 48 hours and release your inspection report and certificate of inspection within 24 hours.

IQMS Inspectors will look for,

When examining the quality of the fabric, different criteria are used by the inspectors

Pakaging Check

GSM Check

Thread Count

Wet & Dry rub test

Greyscale verification

Dimensional Stability

Colour Fastness

Fabric Shrinkage

Tear Resistance verification

Colour Shades

Washing stability

Flame retardant

100% natural fiber verificatioon

FABRIC QUALITY INSPECTION:

THE 4 - POINT SYSTEM?

WHAT IS A 4 - POINT SYSTEM?

The 4-point system for fabric inspections is a standardized method used in the apparel and textile industry to evaluate the quality of fabrics. It is the most commonly used fabric inspection system in the industry. This system evaluates and grades fabrics, giving buyers and suppliers insight into the quality of their fabric.

The system is under ASTM D5430-93, a standard test method for determining the tensile properties of fabrics. It is published by the American Society for Testing and Materials (ASTM) and is commonly used in the textile industry.

In the 4-point system, defects in both the warp/weft or course/wale directions of fabric will be assigned penalty points using the following criteria:

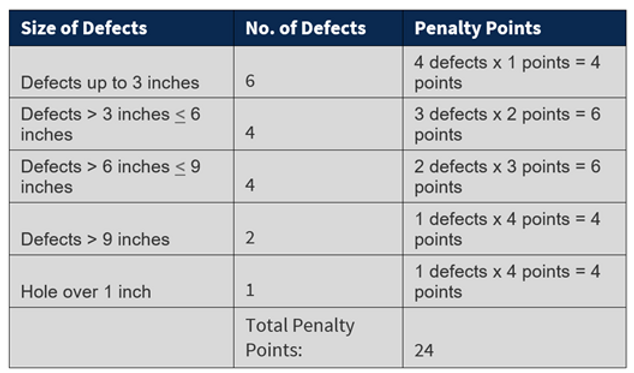

What is the Penalty System of 4 – Point Inspection?

Size of Defects Penalty Points

Defects up to 3” Length / Width (UP TO 75mm) 1 Point

Defects > 3” < 6” Length / Width (75mm > 150mm) 2 Points

Defects > 6” < 9” Length / Width (150mm > 230mm) 3 Points

Defects > 9” Length / Width (More than 230mm) 4 Points

The 4-Point System assigns 1, 2, 3, and 4 penalty points according to the size, quality, and significance of the defect. . At IQMS, defects such as holes, dropped stitches, and torn selvage will be assigned 4 penalty points regardless of the size of the defects. No more than 4 penalty points are assigned for any single flaw. A defect can be measured in either length or width.

Calculation Of Total Points Per Yard

Using the 4-point system, fabric quality is determined by the number of points per 100 square yards.

Points per 100 square yards are calculated as follows:

Points / 100 sq. yd. = (Total points in roll * 36 * 100)/ (Fabric length in yards * Fabric width in inches)

Example: A fabric roll 120 yards long and 46 inches wide contains the following defects.

Calculation of Total Points Per Yards?

Answer : (24 X 3600) / (120 X 46) = 15.652 Points per 100 square yards.

The defects are Acceptable.

What is an Acceptable Level?

It is up to the client to set the maximum number of defects per 100 yards, which is a maximum of 20-40 points per 100.

In general, acceptable level of ‘points per 100 linear yards’ or ‘points per 100 square yards’ are different for different fabric types.

For example:

For Cotton Twill/Denim 28 points per 100 square yards (23 points per 100 square meters) for individual fabric roll

For All synthetic fabrics 20 points per 100 square yards (16 points per 100 square meters) for individual fabric roll

WHY SHOULD YOU NEED

FABRIC INSPECTION?

Easy to identify and classify damages

Easy to overlap damaged area when spreading and cutting processes

To avoid rejects due to fabric quality and faced with an unexpected loss in manufacturing

Ensures to minimize the rejection of cut panels or rejected garments due to fabric faults.

Reduce production delays with automation

Reduce rejects, improve efficiency, and timely deliveries.

The primary goal of any business is to prevent defects in the first place.