PRODUCT INSPECTION

A product inspection refers to a systematic process of checking the quality of a product based on a specified set of standards and insure on-time delivery.

Pre-shipment Inspection (PSI)

A product inspection refers to a systematic process of checking the quality of a product based on a specified set of standards and insure on-time delivery.

Identify the total order quantities are ready for the shipment ?

Are supplier products complaints with the client’s specification and safety requirements?

Is the products quality acceptable base on ISO 2859-1standed ?

Decrease the risk of delivery delay and unsatisfactory products.

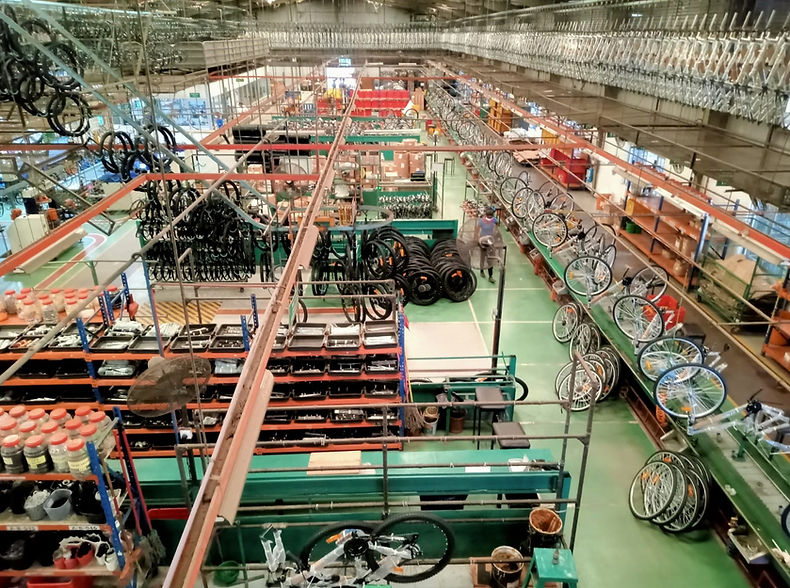

During Production Inspection (DUPRO)

We perform During Production Inspections, to ensure goods are delivered on time, as per customer quality stands by monitoring the production momentum and quality.

Provides an overview of all manufacturing process and identify the real production status.

Managing your production schedule more effectively.

Improving the quality of your products by “nipping” the problems in the “bud”.

Make sure the supplier can deliver on time.

Avoiding monetary losses due to reworking and returned orders.

Increasing customer satisfaction that will be based on high-quality, on-time deliverables.

Pre- Production inspection (PPI)

Conducted once raw materials are received at the factory and they are ready to begin production.

Verify all raw material status ready to start production.

Verify the condition of materials.

Inspect the factory facilities and machinery are ready.

Customer product specifications and stranded well understood by the supplier.

Container Loading Supervision

Container Loading and unloading inspection service guarantee all conditions are met to ensure that your finished products are correct and the actual ordered quantity is securely loaded and delivered of the expected goods to consumers.

Ensure your products are transported in the appropriate conditions.

The right products are being loaded into the container conform shipping Marks, packing & Labelling

The goods are loaded properly to avoid damage.

The products are packaged and shipped as per conditions stated on the sales contract.

Virtual Inspection

Obviously, when travel became restricted and in-person interactions were limited, businesses needed to find a way to perform inspections without having any physical contact. The remote virtual inspection was formed.

When there is a travel restriction in my manufacturing region.

When the supplier’s factory is under lockdown.

Supplier factory located remotely.